to Metals

to Corrosion and oxidation

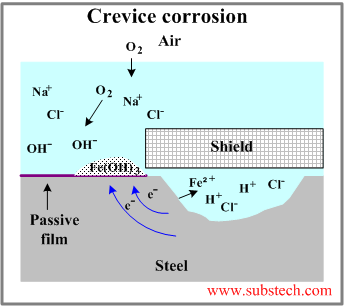

Crevice corrosion

Dr. Dmitri Kopeliovich

Crevice corrosion is an electrochemical oxidation-reduction (redox) process, which occurs within localized volumes of stagnant solution trapped in pockets, corners or beneath a shield (seal, deposit of sand, gasket, fastener, etc.).

Crevice corrosion is considered much more dangerous than uniform corrosion since its rate is 10-100 times higher.

Crevice corrosion is highly accelerated if chloride, sulphate or bromide ions are present in the electrolyte solution.

Stainless steels, Aluminum alloys and other metals forming a passive oxide layers on their surfaces in electrolytes and atmosphere are sensitive to crevice corrosion.

Mechanism of crevice corrosion is similar to that of Pitting corrosion: dissolution of the passivating film and gradual acidification of the electrolyte caused by its insufficient aeration (Oxygen penetration).

In presence of chloride ions corrosion proceeds by autocatalytic mechanism. Crevice corrosion of steel is illustrated in the figure.

In presence of chloride ions corrosion proceeds by autocatalytic mechanism. Crevice corrosion of steel is illustrated in the figure.

Anodic reactions inside the crevice:

Fe = Fe2+ + 2e- (dissolution of iron)

The electrons given up by the anode flow to the cathode (passivated surface) where they are discharged in the cathodic reaction:

1/2O2 + H2O + 2e- = 2(OH-)

As a result of these reactions the electrolyte enclosed in the crevice gains positive electrical charge in contrast to the electrolyte surrounding the crevice, which becomes negatively charged.

The positively charged electrolyte in the crevice attracts negative ions of chlorine Cl- increasing acidity of the electrolyte according to the reaction:

FeCl2 + 2H2O = Fe(OH)2 + 2HCl

PH of the electrolyte inside the crevice decreases (acidity increases) from 6 to 2-3, which causes further acceleration of corrosion process.

Large ratio between the anode and cathode areas favors increase of the corrosion rate.

Corrosion products (Fe(OH)3) form at the crevice resulting in further separation of the electrolyte.

Means of crevice corrosion control:

- Design avoiding stagnant zones (corners, pockets);

- Welding instead of bolted and riveted joints;

- Drain holes;

- Selection of appropriate material;

- Control of the electrolyte composition (PH, chloride ions);