to Composites

to Polymer Matrix Composites

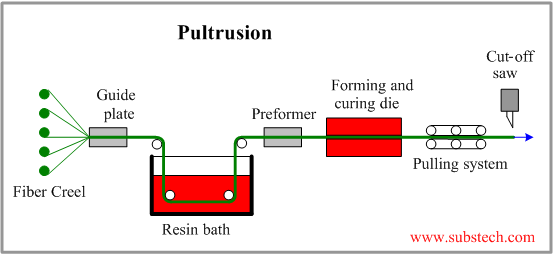

Pultrusion

Dr. Dmitri Kopeliovich

Pultrusion is an automated, highly productive process of fabrication of Polymer Matrix Composites in form of continuous long products of constant cross-section.

A scheme of the process is presented on the picture:

Pultrusion process involves the following operations:

- Reinforcing fibers are pulled from the creels. Fiber (roving) creels may be followed by rolled mat or fabric creels. Pulling action is controlled by the pulling system.

- Guide plates collect the fibers into a bundle and direct it to the resin bath.

- Fibers enter the resin bath where they are wetted and impregnated with liquid resin. Liquid resin contains thermosetting polymer, pigment, fillers, catalyst and other additives.

- The wet fibers exit the bath and enter preformer where the excessive resin is squeezed out from fibers and the material is shaped.

- The preformed fibers pass through the heated die where the final cross-section dimensions are determined and the resin curing occurs.

- The cured product is cut on the desired length by the cut-off saw.

Pultrusion process is characterized by the following features:

- High productivity.

- The process parameters are easily controllable.

- Low manual labor component.

- Precise cross-section dimensions of the products.

- Good surface quality of the products.

- Homogeneous distribution and high concentration of the reinforcing fibers in the material is achieved (up to 80% of roving reinforcement, up to 50% of mixed mat + roving reinforcement).

Pultrusion is used for fabrication of Fiberglasses, Carbon Fiber Reinforced Polymer Composites and Kevlar (aramid) fiber reinforced polymers.

to top