Main page

About us

Sliding Bearings Consulting

Advertising Opportunities

to Metals

to Metal properties and tests

Adhesion tests

Dr. Dmitri Kopeliovich

The strength of a coating adherence to the substrate is its principle functional characteristic.

Adhesion strength is a force required for separation of two adhered parts along the interface.

A wide variety of the coating materials, their thicknesses, the methods of deposition and the functions of the coatings does not allow utilizing a single standard method of testing adhesion.

Particular difficulties are caused by the attempts to perform a reliable quantitative adhesion test.

All adhesion tests are based on different methods of separation of a coating from its substrate at a particular load.

It is important in any adhesion test method to apply the separation load in a repeatable manner. This allows to compare the results obtained by the method.

Sometimes the coating is separated from the substrate not along their bonding interface but throughout one of the materials (coating or substrate) - by the mechanism of cohesive failure (internal failure of the adhesive layer).

In spite of the fact that such failure mode is related to the bonding strength of the coating, it does not characterize the adhesion strength.

Adhesion strength reaches its maximum limit when it exceeds the cohesive strength of the bonding. In this case the adhesion is considered perfect.

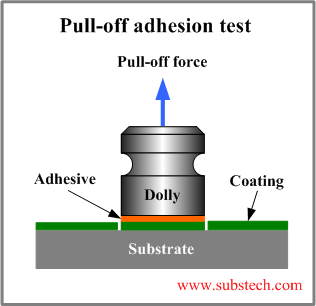

Pull-Off Test

In the Pull-Off Test the load is applied perpendicularly to the coating surface similar to the tensile test used for measuring tensile strength of materials.

The loading fixture (dolly, stub) is attached to the coating by an adhesive.

The load applied to the dolly is increased gradually until the coating is separated (peeled off) from the substrate.

The test may be terminated at a specific value of load if this value is set as the required minimum level of the adhesion strength.

I the Pull-Off Test the tensile strength of the coating bonding is measured therefore its results are not directly comparable with other test methods where the shear stress is applied.

Another limitation of the Pull-Off Tests is the strength of the adhesive bonding between the dolly and the coating surface. The failure occurs along this surface if it is weaker than the adhesion of the coating to the substrate.

to top

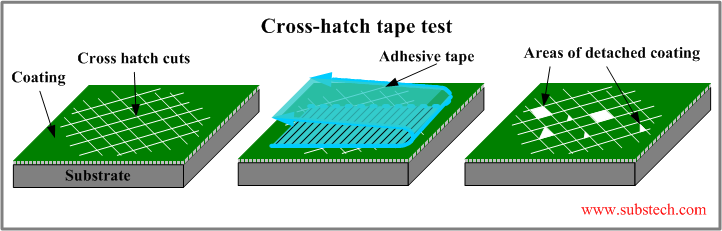

Tape Test

The Tape Test is the most widely used and practicable adhesion test.

The Tape Test is also called Cross Cut Test. At first the tested coating is cleaned and degreased and then cut through to the substrate with a sharp tool (blade, knife, razor) in order to produce edges from which the coating may be then lifted up (peeled off).

The cutting patterns may be different. The most popular patterns are X like (two cuts at an angle 30-45°) and the cross hatch pattern - a right angle lattice with a distance between the cuts 0.04-0.12” (1-3 mm).

A strong adhesive tape is applied over the cut area and tightly pressed and adhered to the coating surface diagonally across the pattern.

Then the tape is pulled back parallel to the surface. If fragment of the coating are lifted up and removed from the substrate the adhesion strength is considered imperfect.

The tested area is examined with a magnification glass and the adhesion strength is rated according to the amount of the removed coating.

to top

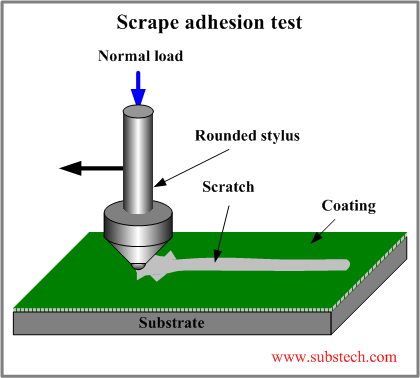

Scrape Test

The Scrape Test utilizes the load applied by a rounded stylus pressed normally against a moving coated panel.

The panel used in the test is flat and smooth with uniform thickness.

The stylus tip makes a scratch on the coating surface.

The load is increased gradually and at a certain value the coating starts to fail producing torn edges with lifted coating along the scratch.

Only the tests performed under the same conditions (shape of stylus tip, loading rate, stylus speed, coating thickness) may be compared.

The critical value of the load may be determined by one of the following methods: examination of the scratch in a microscope; measuring the coefficient of friction; analyzing the recorded acoustic emission.

to top

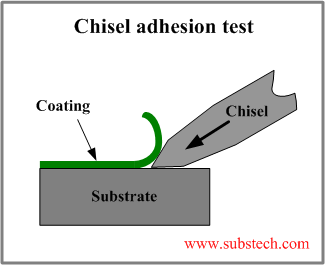

Chisel Test

In the Chisel Test the adhesion strength of a coating is tested by a chisel penetrating through into the interface between the coating and substrate.

In order to expose the interface cross section, the tested article may be cut by a saw.

The adhesion strength is considered perfect if the chisel tip moves not along the interface itself but throughout one of the materials producing an internal failure according to cohesive mechanism.

Chisel Test is commonly used for testing relatively strong (metallic) and thick coatings (thicker than 0.005”/0.125 mm).

For the evaluation of the adhesion strength of softer and thinner coatings a knife is used as an instrument for separation (lifting up) the coating from the substrate.

to top

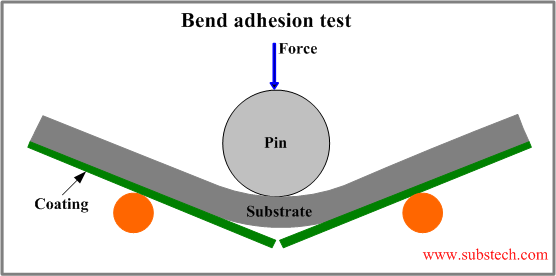

Bend Test

The Bend Test is based on producing shear stress along the coating interface by bending the tested article over a round pin.

The pin diameter is four times grater than the article thickness.

The coating cracks in the bent area. If the adhesion strength is unsatisfactory the coating may be lifted up from the cracked area by a knife or other sharp tool.

to top

Heat-Quench Test

In the Heat-Quench Test the tested article is heated in an oven and then quenched in water.

Imperfect adhesion is indicated by blisters formed by the coating.

The bonding between the coating and the substrate below the blisters is broken as a result of shear stress generated by abrupt cooling (quenching) of the coating and the substrate having different values of the Coefficients of Thermal Expansion.

If the heating-quenching procedure does not change the work piece properties and does not cause its oxidation the Heat-Quench Test is non-destructive.

to top

Burnishing Test

In the Burnishing Test the coating is rubbed by a tool with a spherical tip.

The tool is pressed against the tested article at a specified load perpendicular to the coating surface.

The tool does not scratch the surface but it produces a shear stress which may peel off the coating from the substrate.

Strain hardening (strengthening by cold-work) of the coating as a result of burnishing operation should be taken into account.

to top

Related internal links